Induction Furnace

S-Series

The S series medium frequency power supplies with power ratings from 550 KW to 18000 KW and frequency range of 100 Hz to 4000 Hz have been work horses across the foundries and steel melting plants for their robust design, state of the art technology, efficiency and excellent reliability.

E-Series

The E series medium frequency power supplies have power ratings from 25 KW to 450 KW and frequency range of 200 Hz to 10000 Hz. These power supplies are ideally suited for relatively smaller ferrous and non ferrous foundries with ET ALUMIN SL furnaces of capacities up to 1000 Kg. The current fed inverter design results in higher inverter efficiency. Less number of power components and component types makes the system very simple. The fast electronic tripping devices protect the system in the event of short circuits.

I Series – IGBT

These compactly built power supplies adopt IGBT based design and are available at power ratings from 550 KW to 750 KW and frequency range of 500 Hz to 1000 Hz. A high power factor of 0.99 is achieved throughout the melt cycle.

EI Series – IGBT

EI Series Power Supplies combine the features of E Series and I Series and are available in power ratings of 50 KW to 450 KW and frequency range of 500 Hz to 10000 Hz. These compactly built power supplies adopt IGBT based design. A high power factor of 0.99 is achieved throughout the melt cycle.

ET Double –Track

ET Double-Track is the double output power supply available to foundrymen for optimum utilization of installed KVA. These systems allow simultaneous sharing of power between two furnaces in any ratio within the rated power. Infinite power sharing feature has the potential to increase the KVA utilization index by up to 25-30%. Field reports indicate an increased metal output of 25-30% with ET Double – Track compared to single output power supplies.

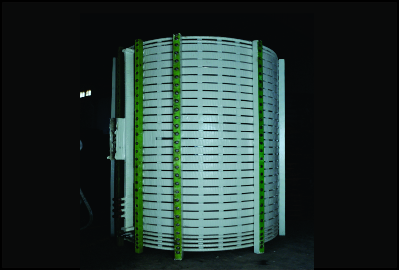

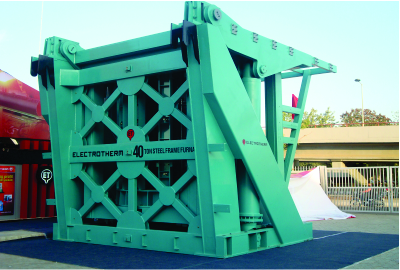

ET- Steel Frame Furnace

- ET Steel frame melting furnaces are available in capacities ranging from 500 Kg to 50 Tons.

- These furnaces are ruggedly built with heavy structural steel for trouble free operation under harsh melt shop conditions.

- Thick walled rectangular coil sections are used to minimize coil losses. The higher coil efficiency ensures energy savings and higher productivity.

- Special coil insulation prevents inter turn sparking.

- Insulated furnace lid is provided to reduce heat loss through radiation.

- Fume extraction ring / Fume extraction hood provided to capture smoke and fumes.

- Coil supports maintain inter turn gap and enhance the rigidity of The coil assembly.

- Insulated furnace lid is provided to reduce heat loss through radiation.

- Fume extraction ring/ fume extraction hood provided to capture Smoke and fumes.

Image Gallery

https://www.nosa-co.ir/index.php/en/product/melt-shop/induction-furnace.html#sigProGalleriaad26115858