SL/RN

Direct reduction is defined as the process by which metallic iron is produced by reduction of iron oxide (iron ore or pellets) below the melting point of any material involved in the process. The product of direct reduction process is called Direct Reduced Iron (DRI) or Sponge Iron. Direct reduction processes are gaining importance because the product from the process has proved to be better substitute of the scrap for the following reasons:

The chemistry of the scrap is not consistent. The tramp elements vary widely, while sponge iron as a manufactured product has constant quality.

Bulk density of the scrap also varies widely.

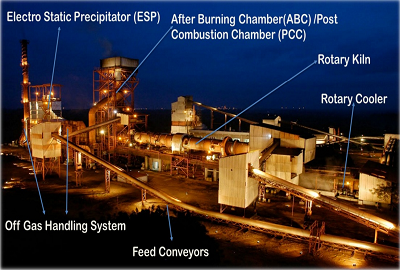

The main equipments used in the process are Rotary kiln, Rotary cooler and gas handling, cooling and cleaning system. The rotary kiln serves the following functions:

A conveyor of solids.

A heat exchanger.

A vessel for carrying out complex chemical reactions.

Image Gallery

https://www.nosa-co.ir/index.php/en/2014-12-30-18-26-51/2015-04-06-10-26-50/sl-rn-en.html#sigProGalleria3e501c2e71